- General

- August 1, 2018

- 8 minutes read

3D printing startup Formlabs raises $15 million, Goes unicorn and adds former GE head and NEA partner Jeff Immelt to board

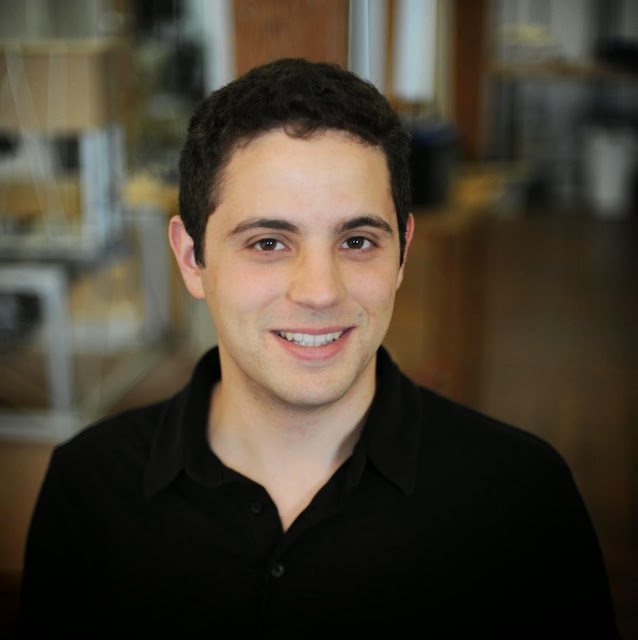

Formlabs co-founder and CEO Maxim Lobovsky Formlabs Massachusetts based 7 year old 3D printing startup Formlabs has hit unicorn status…

|

| Formlabs co-founder and CEO Maxim Lobovsky |

Formlabs

Massachusetts based 7 year old 3D printing startup Formlabs has hit unicorn status with a $15 million Series D funding round led by New Enterprise Associates which values the company at over $1 Billion bringing the total raised by Formlabs to just above $100 million as the startup also adds former General Electric Chairman and CEO and now NEA partner Jeff Immelt as a new member of its board.

Founded in 2011 by 3 graduates out of MIT’s Media Lab, Formlabs has focused its 3D printing efforts on the professional side offering its products to dentist and jewellers and having done a good job of selling over 35,000 printers over the past 6 years.

Formlabs now adds a figure to the number of 3D printing unicorns worldwide boosting its statistic to now 3 of them consisting of itself, Carbon 3D and Desktop Metal.

|

| Depiction of Formlabs 3D printed custom earbuds

Formlabs

|

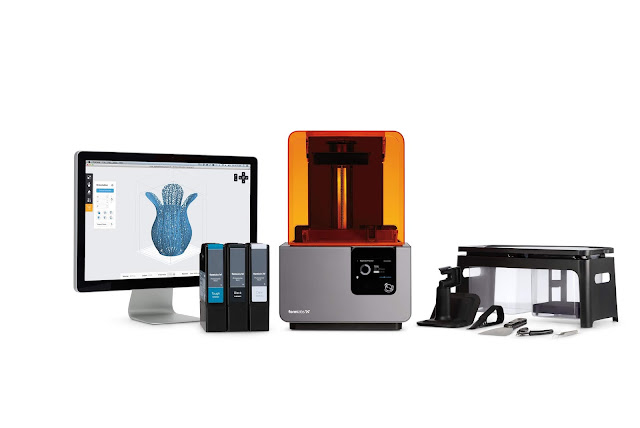

Kicking off with a successful Kickstarter campaign in 2012, Formlabs raised nearly $3 million from over 2,000 backers which marked the starting point for its creative 3D design hardware starting with the Form 1 3D printer and having released other versions consisting of the Form 2 and Fuse 1 3D printers with Formlabs also offering several bundled and mass customization services based on its printers.

“We’re thrilled to have Jeff join the board,” said Max Lobovsky, co-founder and CEO of Formlabs. “Advancing the use and development of advanced manufacturing technologies across a variety of industries is a signature achievement of his tenure at GE, and his depth of expertise will be invaluable to our business. With Jeff’s appointment and this latest round of funding from NEA, Formlabs will be well positioned to continue its global growth and expansion into more product lines.”

|

| Formlabs’ Form 2 3D Printing system |

Formlabs

With Formlabs now being the major seller of stereolithography 3D printers on a global scale and a current $100 million annual revenue run rate, The 500 employee company grasps its title as being one of the major players in the ever growing 3D printing industry which continues to see increasing usage across industries and in turn households which continues to adapt its usage as time goes by.

Formlabs now boast locations across Gemany, China and Japan in addition to its Boston headquarters having gone way further from its beginning at the MIT Media Lab and Center for Bits and Atoms. The startup has established an industry benchmar for professional 3D printing across various fields of engineering, manufacturing, designing, Healthcare, Dentistry, Jewelry, Education and Audiology among other fields.

|

| A large R2-D2 sculpture made from multiple parts printed on the Form 2 and assembled by Formlabs engineer Adrian Tanner |

Formlabs

“I’m excited to work with Formlabs at this pivotal time in the company’s development,” said Immelt. “Max and the team have demonstrated outstanding progress to date, with best-in-class technology and impressive momentum across a wide swath of industries, including engineering, healthcare and manufacturing. Since the company’s founding in 2011, they have outpaced competitors and established themselves as a leader in 3D printing. I look forward to supporting this next phase for the company as they accelerate adoption and continue to advance the technology.”

“We have been tracking Formlabs as their printers have expanded from individual usage to enterprise usage and now they are driving the production of a wide array of end use polymer based parts,” said NEA partner Dayna Grayson, who led the firm’s investment in Formlabs. “The leadership team has executed flawlessly at each stage, and we’re excited to support the growth of this phenomenal company as we enter a new era in manufacturing – one in which scaled processes like mass customization are finally possible.”